- Medical device manufacturing: stainless steel seamless pipe has excellent corrosion resistance and biocompatibility, so it is widely used in medical device manufacturing. It can be used to manufacture medical devices, oxygen delivery, etc., ensuring medical safety and long-term use.

- Aerospace field: Stainless steel seamless pipe has important applications in the aerospace field. It can be used to manufacture critical components such as fuel systems and hydraulic systems, and has the advantages of high strength, light weight and corrosion resistance, helping to improve the performance and safety of aircraft.

- Petrochemical industry: stainless steel seamless pipe is widely used in the petrochemical industry. Due to its corrosion resistance and high temperature performance, it can be used to manufacture reactors, pressure vessels, heat exchangers and other key equipment to ensure the safety and stability of chemical production.

- Marine engineering: Stainless steel seamless pipe is also more and more widely used in the field of Marine engineering. It can be used to manufacture ship pipelines, seawater desalination equipment, offshore oil and gas field facilities, etc., and can be used in the Marine environment for a long time and maintain stability.

- Food industry: stainless steel seamless pipe is widely used in the food industry because of its hygiene and corrosion resistance. It can be used to manufacture food processing equipment, transportation pipes, storage containers, etc., to ensure the safety and hygiene of food.

- Nuclear energy field: stainless steel seamless pipe has good corrosion resistance and high temperature performance, so it is also important in the field of nuclear energy. It can be used to manufacture nuclear reactor cooling systems, fuel rod shells and other key components to ensure the safety and operational stability of nuclear energy facilities.

- Electronics industry: stainless steel seamless tubes also have certain applications in the electronics industry.

Product Parameters

Standard | ASTM |

Place of Origin | China |

Section Shape | Round |

Alloy Or Not | Alloy |

Delivery Time | 8-14 days |

Brand Name | Dashi Jiushin |

Model Number | 300 series, 400 series, etc |

Application | decoration, building, sanitary, etc |

Welding Line Type | Seamless |

Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

Model Number | 201/202/304/316/316L/430 |

Steel Grade | 200/300/400 Series, 301L, 321, 410L, 304 |

Application | Exterior decoration; Architectur; Evevator; Kitchen; Ceiling; Cabinet; Advertising nameplate; Roof structure;Shipbuilding |

Tolerance | ±0.3% |

Surface finish | 2B/8K/Mirror/No.1, etc |

Size | Outer Diameter: 10-2000mm or as customer’s requirements |

Thickness: 0.1-100mm or as customer’s requirements | |

Length: 1-12m or as requirements | |

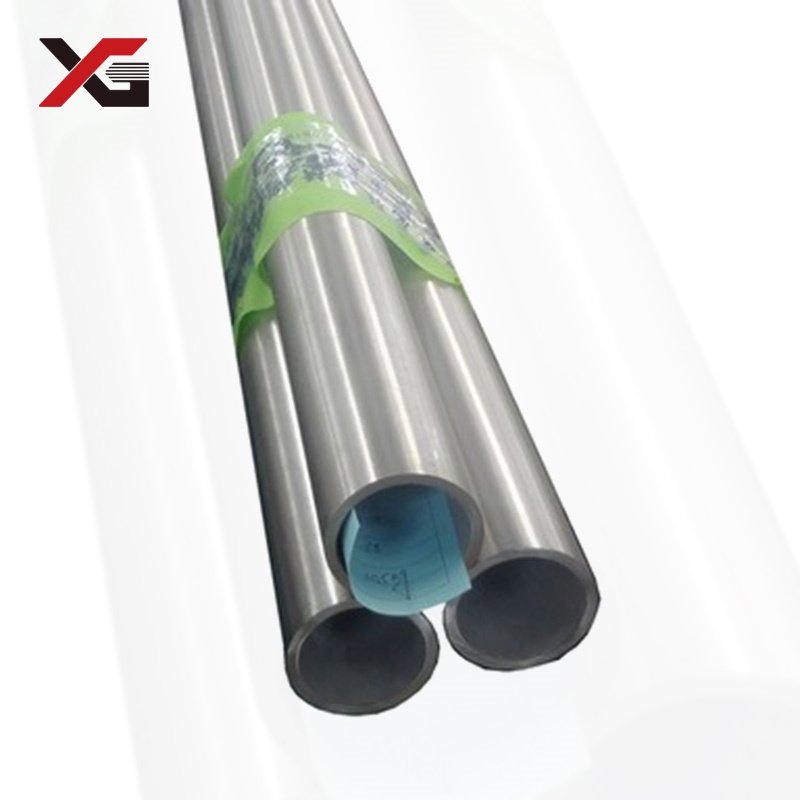

Package | Standard Seaworthy Package |

Length | 1-12m or as your requirements |

Item | 201/202/304/316 Stainless Steel Tube |

Product Specifications

Normal Size(mm) | |||

Ф21×4 | Ф87×17.5 | Ф121×19 | Ф168×19 |

Ф21×4.5 | Ф89×6-12 | Ф124×6.5 | Ф168×8 |

Ф22×6.5 | Ф89×15 | Ф127×10 | Ф170×25 |

Ф25×8 | Ф89×17 | Ф127×13 | Ф172×18 |

Ф28×8 | Ф91×7.5 | Ф127×8 | Ф180×10 |

Ф30×10 | Ф92×12 | Ф130×12 | Ф180×18 |

Ф30×8 | Ф95×10 | Ф130×18 | Ф180×6 |

Ф32×8 | Ф95×12 | Ф133×6-12 | Ф180×8 |

Ф34×6 | Ф95×16 | Ф133×18 | Ф183×18 |

Ф34×8 | Ф95×20 | Ф140×8-12 | Ф185×18 |

Ф38×10 | Ф95×5.5 | Ф140×15 | Ф185×20 |

Ф38×8 | Ф95×8 | Ф140×20 | Ф192×18 |

Ф40×10 | Ф100×8.5 | Ф142×18 | Ф194×10 |

Ф40×8 | Ф100×13 | Ф145×18 | Ф194×16 |

Ф42×5-10 | Ф102×6-10 | Ф146×10 | Ф196×16 |

Ф45×6-12 | Ф102×15 | Ф146×12 | Ф196×24 |

Ф48×5-10 | Ф104×8.5 | Ф152×10 | Ф200×20 |

Ф50×8-12 | Ф108×6-10 | Ф152×12 | Ф219×6-12 |

Ф51×10 | Ф108×13 | Ф152×14 | Ф219×15 |

Ф55×10 | Ф108×15 | Ф152×20 | Ф245×10 |

Ф57×6-10 | Ф110×6 | Ф152×6 | Ф250×25 |

Ф60×6-12 | Ф114×6-10 | Ф152×8 | Ф273×6-12 |

Ф65×6-12 | Ф114×13 | Ф159×6-10 | Ф273×34 |

Ф68×6-12 | Ф114×17.5 | Ф159×12 | Ф325×8-10 |

Ф70×8 | Ф116×12 | Ф159×15 | Ф355×14 |

Ф70×10 | Ф116×8 | Ф159×18 | Ф377×10 |

Ф76×6-12 | Ф118×2 | Ф159×22 | Ф406×14 |

Ф80×8-12 | Ф121×6-11 | Ф168×10 | Ф457×14 |

Ф83×8-12 | Ф121×16 | Ф168×12 | Ф508×15 |

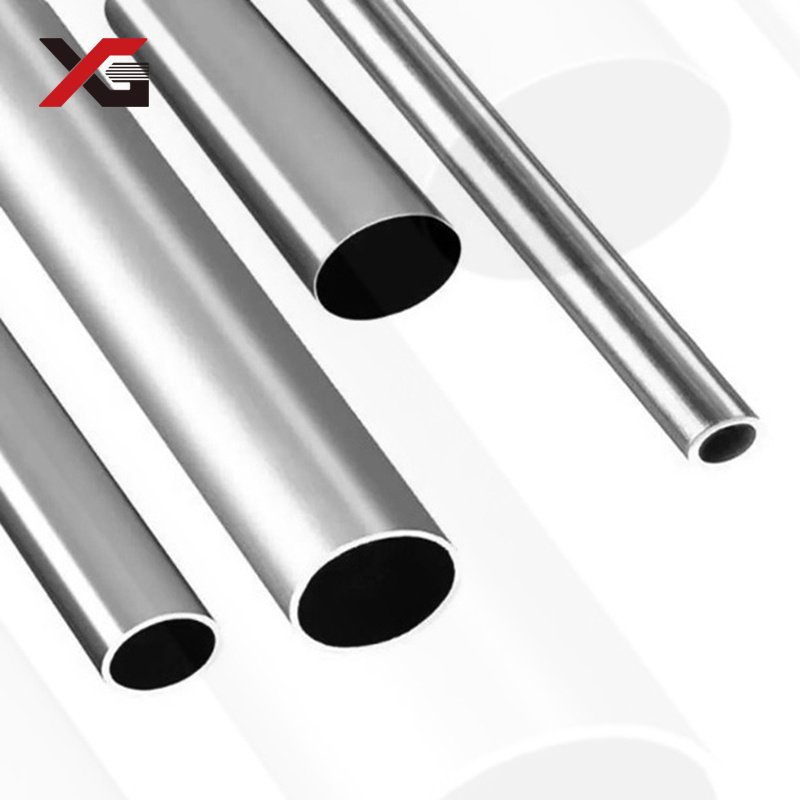

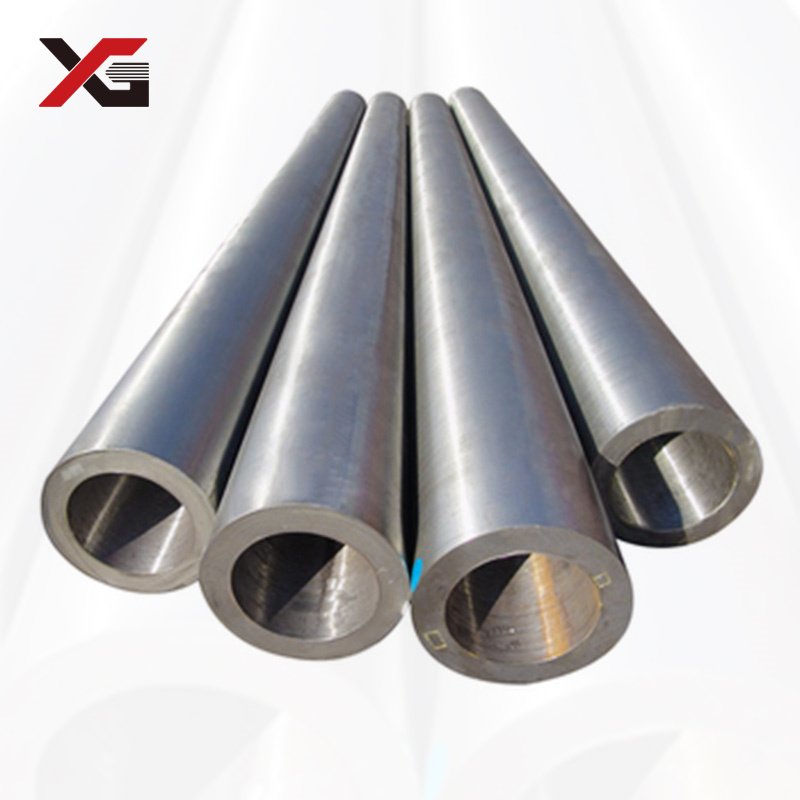

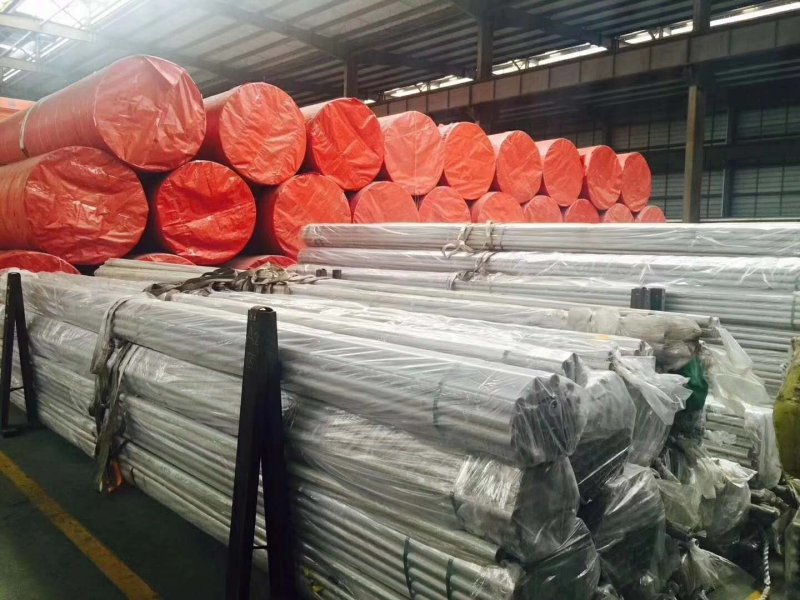

| Product Details | Product Production | Product Warehouse |

|  |  |

|  |  |

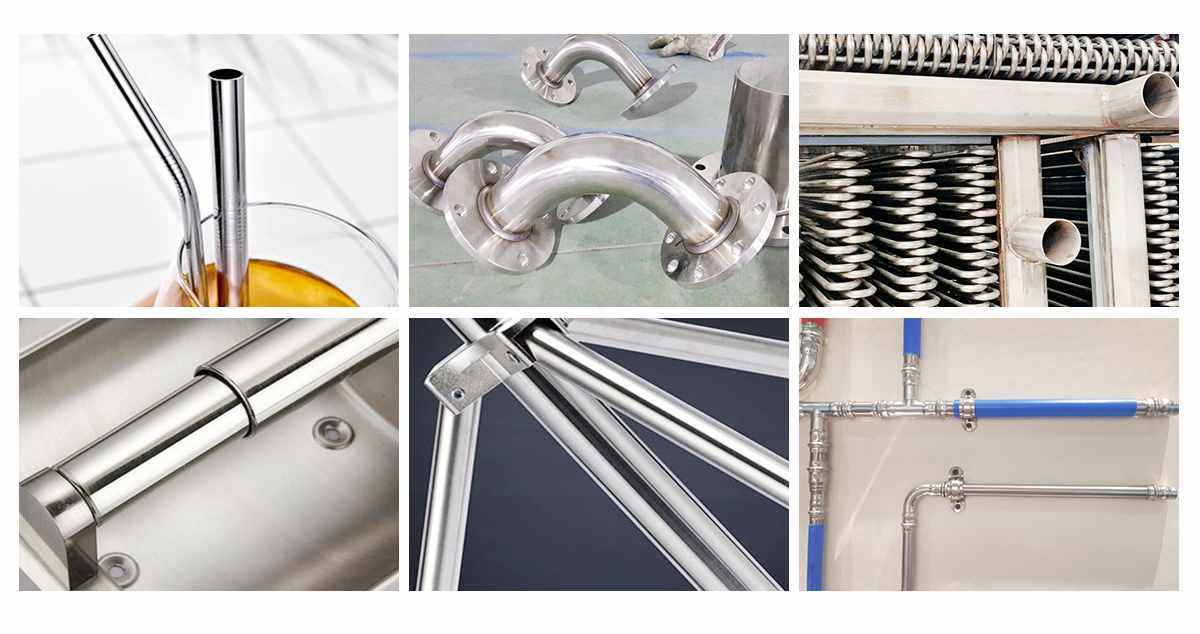

Applications

Stainless steel pipes are widely used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical, medical, food, light industry, mechanical instruments, etc. In addition, when the bending and torsional strength are the same, the weight is relatively light, so it is also widely used in the manufacturing of mechanical parts and engineering structures. It is also commonly used as furniture, kitchenware, etc.

Project Cases

Additional Processing Technology

We can provide additional treatment processes such as cutting, marking, spraying, welding, bending, punching, and surface treatment for stainless steel pipes.

Product Packaging

Product Transportation